Saturday, November 17, 2012

EV Club

Join me in tracking your EV at http://evclub.org.

This is a handy sight a friend of mine put together to track your EV miles, fuel saved, money saved, carbon reduction, etc.

You can now follow my EV statistics on right side of this blog.

Check it out!

Monday, September 3, 2012

Petition Time

https://petitions.whitehouse.gov/petition/we-should-support-oem-and-aftermarket-plug-vehicles-same-tax-incentives/V8qMBrGN?utm_source=wh.gov&utm_medium=shorturl&utm_campaign=shorturl

Monday, August 20, 2012

Back on the road. Take 3, or is it 4 now?

I've mounted my CellLogs further from the trunk lid. Hopefully this will keep the heat down and reduce my chances of further electronic glitches from. I'm still thinking this was the case of the failure, but don't have any proof without being there.

Tuesday, August 7, 2012

Battery Failure

I had lost a cell. It had expanded upwards! Here are some more pictures after I had removed it from the car.

Wednesday, June 27, 2012

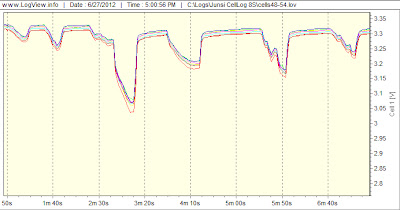

Battery load testing

I'm frequently getting low voltage alerts (<2.5v) while driving and was curious how many cells were meeting this criteria. First I'll recheck the torque on the batteries, but assuming thtat is fine, it looks like I can replace the one cell and fix this. My normal driving never reaches 3C range unless I'm really needing to pass somebody. Replacing this one cell should remove the low voltage alerts most of the time. I have an extra cell sitting around that I've tested at 160Ah capacity. I'll replace cell 5 with it and hope the voltage sag on it is closer to the averages seen here.

Sunday, June 17, 2012

Heatsink replaced

I got some time yesterday and installed a new heat sink that I think will be more efficient while driving. I mentioned before the old heat sink below has the fins parallel with the controller, but the air while driving is perpendicular to the fins.

Thursday, June 14, 2012

This is cool!

Now that I'm driving to work again, and the heat is coming, I figured it was time to rebuild the AC system. There was quite a bit of machine work needed, so luckily my uncle Duane had some time yesterday. The main pulley was bored out to 7/8" and a new key way made. A thin bushing was made that went on the shaft first. This slid to the furthest inward point on the shaft and allowed us to tighten against that and not allow anything to slowly walk in and rub on the housing. Next, I reinstalled the Netgain RPM sensor and finally the main pulley went back on. A 3/8" bolt, custom washer, and some Loctite then went on to keep everything in place. The mounting brackets base had to be cut and slid outwards about 1/4" to account for the new position of the main pulley.

Here are some pictures of the final system. You can see I reused the auto tension pulley from the original serpentine belt system. I reused the same belt I purchased the first time I did the AC. Luckily it was still the right length even after the positioning of the components shifted a bit.

Monday, June 11, 2012

Back to work

Air Conditioning:

The weather is going to start heating up. Later this week I have plans to meet up with my uncle and get some machine work done. Afterwards, I can rebuild the brackets to mount the compressor and I should have a comfortable commute home in the afternoon. I'll post some pictures of the AC system when completed.

Sunday, June 3, 2012

My worst cell

I drove 65 miles and brought it home using 137 Ah. At this point my check engine light was coming up with only about 1C draw so I new at least one cell was getting low. I saw that my voltages were fairly well scattered around which was expected considering how scattered the self discharge seems to be.

Below are the photos of each cells voltage starting from the back of the car and working forward. There is one cell at 2.7v. This cell is basically dead and my worst cell. I'll probably yank or replace at least it. I have two more cells at 2.9 which means there is maybe another 5Ah in them tops. Most of the remainder of the pack is around 3.1. I'm guessing there is at most 10Ah in these cells. On the last two pictures you'll see sequentially 10 cells which are all 3.25v. These are the additional cells I added about 1.5 years go which have almost no miles on them compared to the others. They are still happy and have at least 20-25Ah left in them I'm guessing.

So this means that my worst cell is still giving me just over 85% capacity after four years. If I hadn't over charged some cells slightly, and over discharged multiple times, and never went over the 3C rating, I would be a bit upset. Considering the abuse I'm guessing this is right on par with what's to be expected.

So now I'm debating what to do. Ultimately I'm thinking I'd like to go with a much higher pack, say 350v using 100Ah CALB cells. These cells are now rated at 4-5C with 10 second bursts of 8C! This would require multiple changes. First and obviously the pack needs to be completely replaced which isn't cheap. Second the motor controller would need to be replaced with something like the Netgain or Soliton1 which allows high input voltage but you can regulate the motor side voltage to keep it safe. This also equates to even lower cell side amperage draws which should be easier on the cells. I'd also need to replace the charger. No hard feeling here though. The Thundersky charger is twice the size of say the Manzanita Micro charger for the same output (did I mention is weighs twice as much too?).

My other thought is to slowly replace the TS 160Ah cells as they wear out with CALB 180Ah cells. Physically they are identical so no mods would be required. These cells are also 4-5C rated so they can handle the amps my modified Curtis is demanding. I've got some thinking to do.

Either way, before I get back on the road any time soon, the AC needs to be redone. I'll need to engineer the mounting bracket (again) and machine some parts for the pulley. It's a shame it wasn't a direct bolt on replacement from the ADC 9".

It's suppose to cool off next week, so despite no AC, I think I'll drive it to work and see how the batteries hold up before investing any further time.

Tuesday, May 29, 2012

Too much voltage, a new motor, and self discharge.

While driving though I did figure out the cutting out issue I'd been seeing. It was not the motor but the controller itself. It was switching frequencies and making a terrible jerking affect. My friend has now modifed the controller to remove this feature.

The car was done for quite awhile and then not driven at all the last year which led to another interesting discovery. Remember that I dropped all balancing boards to experiment to see the real need for this. Every 3 months or so I'd go out and plug the car back in to charge. Now, after a year I was getting ready to take it on a long drive and notice one cell was very low 3.1v resting. I charged the pack but only to replace about 20Ah in the pack. I then charged the one cell to find it took an additional 60Ah! My first thought was this cell is bad but it turns out most of pack was VERY unbalanced just from the self discharge. Each cell was different taking another 20-60Ah compared, I guess, to some of the better cells that didn't self discharge so bad. I'm in the process of replacing the balancers and getting the pack balanced again. I then plan to do another capacity test on this pack and see what shape it's in. I'm hoping to start driving it to work again when weather permits.

Sunday, November 21, 2010

Back on the road

The original BMS didn't have any wire protection, if for some reason a wire got shorted out and burned up, you'd have to rerun that wire. I added small inline fuses to each cell at the battery. It's a little more cost and time, but something that's worth it in my opinion.

Here is a picture of the completed front end. Six batteries were removed from the original design to all for the AC compressor and pulley assembly. The good news is I finally have AC, but the news is it's winter time and I have to wait awhile to use it. However, part of this was to add the heater and on the cold mornings it really heats up the small cab space of this car quickly.

The motor controller was modified in multiple ways. First the Curtis "whine" was removed and the car is now completely silent, as an electric car should be. The maximum voltage was increased to allow for my fully charged voltage on 54 cells (I charge up to about 184v). Finally the amps was increased from 500 to 750. This made a huge difference in acceleration and overall power. My 0-30 went from (I think it was 7 seconds) down to less than 4 seconds. Overall the total power of the controller went from 72kW to just over 130kW.

I removed that large, and unreliable BMS screen from the dash and replaced it with the E-xpert Pro. This has turned out to be a great little display. On top of showing pack voltage, amps, Ah, and remaining runtime, it has some other extras and is highly configurable. You can customize this meter to your battery, driving needs and how hard you want to push your battery by setting what is considered full, empty, when to raise alarms, etc. So for example I setup mine to alert me when the pack is 30% SOC and to consider 20% SOC empty. This affects how the "fuel" gauge displays its bars. I also turned on a feature that will automatically add the back light as long as >1 amp is going through the shunt. As I drive the back light is on, and 10 seconds or so after stopping it turns off. I also configured the meter to consider the battery full when 184v is reached and the charger is at about 2 amps for at least 1 minute. This then resets the Ah counters and gauge and avoids any calibration errors that might allow the meter to slowly drift over time.

Here is the trunk now. I wouldn't call it finished because things are still a little messy and I'd like to get carpet back in there. Trunk space is still reduce, but I can at least fit something in there now if needed. The little black things on top of the charger are the new Cell Log 8 modules that I'm using to monitor high and low voltage conditions. These are about $13 a piece and will monitor 8 cells each. I build a little circuit board for each to simplify the wiring. They have an internal relay that allows you to provide signalling to the charger, a buzzer, light, etc. They are not isolated, however, so expect to use an additional relay on each module to isolate it. These modules will turn on when the charger is connected to AC power or the key is on.

Another thing I modified this round was the suspension. I added another 9 cells (over 100 lbs) and with so much additional weight in the rear I knew I couldn't avoid it this time. Online I found the spring rates saw that the rear springs were much stiffer than the front. The front springs were 245 lbs/in while the rear springs were 311 lbs/in. I moved the rear springs to the front of the car and replaced the rear with 10" (original springs are 11" unbound) 400 lbs/in springs. The put the rear exactly back to stock ride height and my front is still 1/4" lower but I think within range for alignment. I still need to take the car back down for an alignment to see if this will do.

It's great finally being back on the road. The gas to drive my truck 70 miles to work each day was really adding up. That and I just missed my car, too much fun to drive. I'll keep you posted on miles. I think around 16-17k miles total at this point.

Wednesday, September 8, 2010

Trunk Ventilation

I plan to ensure adequate ventilation this time and have installed two 120mm fans. They will connect directly to the 240v charger source and run continuously during the charge cycle. The fans are quiet (30 dB), low speed (1900 RPM), move up to 67 CFM and take 7.5 watts of power each.

Here is a shot of the mounted fan. The trunk is big ugly at the moment but I plan to reinstall the carpeting after the modifications are complete.

Here is a shot from the bottom of the trunk. I've installed a vent which will deflect water spray while driving. They are angled to take the incoming air which should close the vents as well during speed.

Thursday, September 2, 2010

Motor Cooling

My plan is to install four small fans directly above each set of brushes that turn on when the motor heats up using a thermostat. The thermostat is basically a temperature driven switch that will trigger a relay to turn on the fans. I selected 40C or 105F as the turn on. This will keep it from turning on during short trips but will ensure it starts cooling as soon as possible.

Here are the fans I used. They are 2" fans that do 20 CFM and draw .25 amps.

Here is one of the mounted fans and the thermostat. I made a bracket that attaches to the old temperature sensor and the thermostat bolts to the bracket.

When I manually enable the system I can feel a good breeze coming out the back the motor so that's a good sign. We'll see what happens after I get it back on the road.

Monday, August 30, 2010

More battery testing

When I got the original cells I was told the factory capacity tests were all above 160, if I recall they were mostly around 165Ah. I charged a group of four new cells the same way I did the old cells. That is, not long after switching from CC stage into CV stage I remove charge and begin testing. The old cells were drained at ~130 amps until 2.5v and the worst cells yielded 145Ah, most around 150Ah. The new cells I only drained down to 2.8v and the reason is that at 2.8v they had produced 183.5Ah!

This raised a few thoughts of course and along with the fact they have improved the cells, I'm lead to believe that Sky Energy (CALB) who sells an equal size and weight 180Ah cell for more money is most likely selling the exact same battery. Unfortunately I don't have the 180Ah cells to test, perhaps they are getting 190-200Ah. I believe the batteries might be coming with more capacity also so that after time, they are still considered to be at their rated capacity or higher.

Trunk Mods Part II

Friday, August 27, 2010

Too Cool

The first and probably hardest step determining how power the compressor. My first option was to modify the compressor to use a standard V belt. In this case it was easy to create a main pulley to attach to the motor. However I determined, after dismantling the compressor, it was going to be very difficult. My second option was to find/make a pulley that could use the same style of serpentine belt the compressor used. I opted for this method. I used the original pulley which accepted a spline shaft. The ADC 9" motor has a much smaller, round keyed shaft. I bought a 3/4" hub from tractor supply. I was able to get my uncle to turn down the hub and we then pressed it inside the original pulley with a hydraulic press. We ran a weld around one end to make sure it could turn inside. With this done it was just a matter of fabricating a frame that mounted the compressor and tensioner to the motor frame.

Here you can see completed setup. Reusing the tensioner instead of trying to make the compressor adjustable is the best route. The tensioner keeps the belt at the ideal tension as it stretches with age. This setup should be maintenance free for years.

Here is a shot from the other side.

I ordered from Jegs and got a Gates belt K060345. This is actually a bit over 35" and is the six v serpentine style belt used originally, just much shorter. This was stocked and I got a "free" hat. Considering their "free" shipping had a $5 handling fee, I'm not sure which one of the two I actually got free.

Here is a 12v functional test video. It's not nearly as noisy as this little camera picks up.

After everything was functional I needed to charge the AC system. The system had been opened for months, and even if it had only been opened for a day or so you need to do a lengthy evac process. An oil based vacuum pump is required which I bought one from Harbor Freight. You'll also need an AC manifold set which I also got from Harbor Freight.

The process is fairly simple. First connect the high(red) and low(blue) side hoses to the A/C system. The sizes are different so you can't accidentally connect the wrong one. This manifold set has a yellow hose and two spots where the yellow hose can connect, one is open and the other is a pressure fitting. Connect the yellow hose to the open side and then to the vacuum pump. Turn on the vacuum pump and then open the high and low valves. Let this run for several hours, the longer the better. The pump will get the system down fairly quickly, but it won't remove all the moisture this fast. You must leave it running to remove the moisture (3-5 hrs will do it). Once complete, first close the high and low valves, then turn off the vacuum pump.

You'll need to check the service manual to determine how much refrigerant should go into the system. You'll also need to replace any oil that was lost. There are refrigerants that contain oil, but it's not enough for a complete recharge so you'll need to do the math and figure out what you need.

The recharge process is simple. Read and follow the directions on the can first and foremost. Disconnect the vacuum pump and connect your refrigerant. The can should be shaken during the entire process. Open the valve on the can, then open the LOW side ONLY. Never open the high side valve while recharging. You'll hold the can upright and rotate 90 degrees every few seconds again given the can a good shake frequently. You'll want to make sure there is enough refrigerant and oil in the system before turning on the A/C system (again consult your service manual). Most systems should have a low pressure safety switch to prevent this. With the A/C system on max you'll notice the low side gauge drop as it compresses the gas to the high side. As it pulls from the low side more refrigerant from the can will pass into the system. As the can empties it slows down so be patient 5-15 minutes per can. Repeat this process to add oil and more refrigerant as needed. When complete close the low side valve, then close the refrigerant valve. The high and low side connectors can be popped off easily at this point, but when you disassemble the manifold some gases will escape so do this in a well ventilated area so you don't breath it in.

That was it, now I have some really cold air coming out of my EV!

Thursday, August 19, 2010

Trunk Modifications Part I

- Greater range. More cells means I have more energy and can travel further before recharging.

- Distributed load. The more cells I have, the less they have to work for my daily commute which will increase the life of the cells.

- Performance. Currently the 144v system allows the motor to hit about 4k RPM before the controller switches to VMax. Any additional increase in RPM greatly reduces torque requiring you to shift to a higher gear. Increasing the voltage will allow the torque to remain steady for higher RPM meaning the motor will want to rev out higher.

Here is a shot of the original trunk space. You can see there isn't much usable space currently above the fuel tank, about 3" and it opens up to only about 8-10" on the far right.

The old spot I use to have the charger has a curve to it and greatly reduces the usable space.

Sunday, August 15, 2010

Battery testing

Below is my battery testing solution.

- Costco a 2300 watt power inverter. This allows me to test four batteries at a time to get my 12v source.

- 1500 watt space heater. This gives me just over 130 amp load on the batteries which is close to 1C and will give a decent enough load to test.

- E-Xpert pro battery monitor from TBS Electronics with a 500 amp shunt. This will track the Ah used for me and give accurate results compared to trying to calculate this myself based off of ever changing voltage/amperage as the batteries drain.

- CellLog8 allowed me to easily monitor each cells voltage to determine when a cell was too low during the load test or too high during recharge.

- For charging I used my original battery charger, a 12v charger I had, and my bench power supply. This allowed me to charge up to 45 amps and helped speed up the testing greatly. I only did quick charges and once the amperage needed was between 5-10 amps I stopped charging and begin the test. This means the cells were NOT fully charged (probably 90 - 95% is my guesstimate) which is important when reviewing the results below.

My original testing plan was going to be to drain the batteries until the first cell reached low voltage, then rotate in another cell and continue testing to get results for each cell. After doing this only once I realized that the capacity of the cells was extremely close and it wasn't worth the extra time. I won't post all the results but basically my lowest cell produced 145Ah. I had other groups producing 148, 150, etc. They were all extremely close. Even the two cells that have terrible voltage sag still produced over 145Ah like the others. Now 145Ah is just over 90% of original capacity, however, remember my charging method was manual and I didn't give it the time to do much constant voltage charging. So to my surprise, I think I'm still near original capacity. The only thing is I didn't do this testing when the cells were new and I'm told they will have at least 160 but usually more, so it's possible I've lost more than I know. Either way this is good news and I'm quite happy with the results.

Monday, June 28, 2010

In the name of science part II

I've been in touch with a great guy who works at Curtis. This weekend I had the opportunity to test a modified Curtis 1231C. Unfortunately I only had a 500 amp shunt so we weren't able to test the motor side amps. I did see my battery amps peaking somewhere around 650-700 though as the controller reached Vmax. This controller reduced my 0-30 to 5 seconds. I will add the shunt later and get the real output from it soon.

He also has an even higher end modified 1231C, but we were having some issues with it. It should be 200 amps more or so. It would be nice to see a 3 second 0-30 :)

Unfortunately I can't give out any of the secret sauce that is being used to upgrade/modify these controllers since I didn't obtain the information myself and don't want to get anybody in trouble.

We should be doing some more tests with the 2nd upgraded controller later and I'll be sure to have the shunt ready for some numbers. I realize most people won't be able to make these modifications, but it should give you a good idea of expected acceleration for a given amount of continuous amps.

Tuesday, June 22, 2010

15/100

The increase in temperature has made a little improvement to the increasing voltage sag. I think the bottom line is I'm pushing these cells harder than I should for longevity. I believe my commute to work is using >80% capacity and this is taking a toll on capacity. Some mornings I have cell that is very close to fully discharged. I don't know how many miles I have left before at least one cell can't make it and possibly gets ruined to get me here.

I keep going in circles, but I'm leaning towards not selling it now. I'm thinking of making some modifications though now that I see how reliable the conversion itself is. Nothing official yet but here are some ideas I'm toying around with.

Motor controller: The Curtis 1231C has been reliable but I want to get the acceleration back in this car. I'm leaning towards the Soliton1 again for a few reasons.

- It will increase my motor side amps from 500 to 1000.

- It's much larger and has great cooling with the option of water cooling if needed. In the hot summer days on my long commute doing 70mph the Curtis is kicking down the amps sometimes.

- It has many features that will make protecting the batteries, and motor a breeze. I'd like to add some features, but reduce complexity of the build and I think this will be a good step in that direction.

- I'll have the ability to run a pack voltage that is much higher than the voltage applied to the motor. This allows you to run more smaller batteries allowing you to still get the capacity you want, but make it easier to fit them. It also will remove volt sag during hard acceleration. The pack itself will sag, but if your pack voltage is high enough the motor will receive a steady voltage increasing performance even on those cold days.

Trunk mod:

I think I'll end up cutting out the current trunk and expanding it. There is a LOT of room that is not being utilized under there. This will allow me to add more batteries and even move some of the front batteries to the back giving me room to finally mount that AC that I've been missing.

Batteries:

Currently I'll just add some more cells (I'd like to add another 15 or so) so I can get as much from the existing cells. This should ease up on them and extend there life some on my commute. This will give me not only more capacity but the ability to crank up the motor voltage a bit also to increase high end performance along side of the low end performance I'll gain from the controller change.

BMS:

I'd like to get the car to a point where I don't have to look at anything and worry about what's going on. I want to simplify this side of things most of all. I want to be able to get in the car, look at my "fuel" gauge and know if I'm good to go. If there are any issues, then be able to connect something and diagnose the problem. I'm looking into some options for a low cost over haul here. The biggest problem with adding more and more cells is the complexity of protecting them.

As always, anything I do I'll document and share with you.

Tuesday, April 20, 2010

One year

I decided to do some quick math to see what 12k EV miles really means. The car originally got 26mpg on my commute. 12,000 miles/26 mpg = 461.5 gallons that I didn't burn this year. Gas in my area has been more or less $3 over the last year so that's $1384 dollars I would have spent on gas.

Although it's great to not have given my money to the oil companies or burned the gas, the actual conversion cost vs returns would never pay off before something needs to be replaced (i.e. batteries). EVs of some form are definitely the future, now we just need to wait for all the auto manufactures to get those production models out which will reduce costs. 2011/2012 will be a huge turn for the auto industry...I can't wait!

Wednesday, March 10, 2010

10k miles and counting

You may recall I reported two cells which sagged considerably more than the rest. I figured these would have went out by now but they are still working fine. On the down side, I now have two more cells that seem to sag more than before (about 0.4v under 2C load lower than the rest). I don't plan to replace any of them until they go out completely so I can really test them out. Speaking of replacing them, I noticed that Elite Power Solutions has finally dropped their prices to be more competitive with some of the other suppliers. We'll hopefully see a continuing trend making this option more affordable for all.

Friday, October 30, 2009

When to short is two long

The cell was directly shorted out for a good two seconds, maybe a bit more, although it seemed liked a minute as I was jumping around trying to stop it. :)

I gave the cell a separate charge knowing I had discharged it quite a bit and definitely exceeded the maximum discharge amperage. Somewhere during the first or second week of driving to work the cell didn't have enough capacity to make it here and dropped to zero volts. I knew I had done some damage to it now, not from the zero volt, but the fact that it reached zero volts. If you recall, I've taken another cell to zero volts and it's still alive and kicking so no final verdict there yet.

I manually charged this cell up again for about a day at 5 amps, AFTER the pack itself had reached full charge. This one cell, however, would never fully charge. It seemed it internally had a self discharge of a couple amps maybe.

However, it continued to get me to work...until today. The cell reached zero volts again on the way to work and I knew it was time to replace it. This time, the cell would not charge...at all. I could not get the voltage above 0.7v and the cell got very warm when charging.

So although this is the extreme case of discharging at high rates, it may speak slightly to what happens to a cell when exceeding the maximum continuous ratings, just to a lesser degree. In short, it's bad :)

So, I've now lost my first cell. Luckily it was due to my own ignorance and not a failure for general use.

On a side note, I have noticed much greater voltage sag with the colder weather under load. This may be because the cells don't charge as much in this weather as well as the temperature it self during operation. It's about 45-50F when I leave in the morning and the car charges outside. We'll see how bad it gets when winter really kicks in here.

Friday, October 16, 2009

Is it alive?

Sunday, August 16, 2009

In the name of science

Thursday, August 6, 2009

5000+ miles

In short, that's pretty much what needed to be done to the car, nothing. I did raise the vehicle and get under there for an inspection. I wanted to make sure no bolts were missing or coming loose. Additionally I wanted to check for stress or crack marks in the motor mounts, batter racks, etc, but everything looked perfect.

I'm actually over 6k miles at this point. Roughly I think I have about 100 cycles on the batteries after the 4 months of driving @ 1.25 cycles per commute round trip. This is a pretty rough number, but good enough for general tracking of the cells life over the months and years to come.

Wednesday, July 22, 2009

As bad as it gets, or is it?

A few weeks I was driving to work and looked down at the TS BMS system for kWh. The reading was FAR lower than normal for being halfway to work. My first though was, "crap it didn't charge and I'm halfway between home and work". I decided to keep going and keep light on the throttle. I made it to work with power to spare. It turned out the pack was completely charged when I left home, but the BMS failed to recognize most of the energy that was charged into the pack.

The Post:

It's been about a week ago, and I was just pulling out from work to head home. I noticed the computer again didn't register that it had charged. I assumed it was an error and headed home. Sadly this time it wasn't a false alarm. I drove about 32 of my 35 mile trip home when the BMS started yelling about a low cell. Even more sadly, this didn't alarm me since the computer is always giving me false positives. Regardless I started watching the cells and noticed all of them were a bit low (2.8v on average) with the lowest one being 2.5v or so. As I continued to drive they all started dropping, but one more so than others. I could see it going 2.5, maybe 5 seconds goes by, 2.4v, etc. It didn't take any time to reach zero volts under load. At this point I figured I've lost a cell, but the other were still in the safe zone.

I got home and after turning my charger amps down to 2 began charging. It took a few hours until the cell was up to 2.8v and I cranked it back up to 30 amps and let it charge.

The next day I was hesitant to even try to make it to work, but I figured this is half the fun of owning an EV. I was surprised to find out that not only did I make it to work but that cell was in the top 5 or so under load meaning the internal resistance was not changed and it's still behaving pre-incident.

How much life, if any has been taken away from this cell? No clue and only time will tell if fails before the others. However, and most importantly, this shows these cells are able to take a lot more abuse than I figured.

Wednesday, June 10, 2009

EV Bling

Sunday, June 7, 2009

Solar and PG&E (Pacific Gas & Electric)

The solar is directly connected to the grid through the inverter. The inverter is designed to not send power into the grid if the electricty is off. This prevents the power company from getting shocked if they shut down their side and want to be sure no solar systems are now powering those lines.

So the way it works here is the power company keeps track of the excess energy you produce during the day. This is done in the simplest terms by letting your meter run backwards. Then at night, lets say, when you're not generating any power your meter runs forward again and you recover that excess energy you created earlier. It's really a great setup since you don't have to worry about costly batteries that need replacing.

Additionally, and to some what complicate what I just said, we have a couple of options here and I went with a time of day (TOD) metering. Peak is 1pm-7pm, partial peak is 7-9pm and 9am-12pm, off peak is 9pm - 9am. This is Monday through Friday. The weekends don't have peaks and all holidays are also like weekends. For peak the energy rates start at about 30 cents per killawatt. Partial peak is about 14.5 cents, and off peak is 8.5 cents. What this means is while I'm at work and not using much energy not only am I making excess energy, but it's not really counted on the kW basis. It's tracked as credits in the form of currency. Later at night when I get home and start using the power again I'm buying it back at a cheaper rate than I sold it for. This helps out the power company to supply their power needs during the "peak" for all users and allows me to only require a system that generates about 75% of my energy use.

It gets more confusing yet...Each Peak, Partial Peak, and Off Peak have their own seperate tiers. Tiers, for those who don't aleady have to deal with this, is an alloted amount of energy you can use at a set price. Once you use more than this the price of the power increases. I believe for my power company their are 5 tiers. So even with the right sized system you might end up going up in tiers during off peak (night time and weekends) simply because you don't generate much here. However, you've also been getting paid quite a bit during peak to cover multiple tier pricing during off peak.

So that's how it all works for me with my power company. Hope this clears things up, I know it confuses me more. :)

Friday, May 29, 2009

Elite Power Solutions - Not so Elite

As you're aware for those following along I've had a few, to say the least, issues with the BMS system I purchased from Elite Power Solutions. I've emailed them quite a few times along the way but never really got a fix to anything and it always resulted in me figuring out a work around to make the system happy.

Recently, I thought I had two bad cells. It turns out, again, the BMS was misreporting these cell voltages, but only under load (they show fine at standing voltage, but drop quicker in voltage on under load than they really are). Here is the email transaction. It seems to start off fine, but after well over a month, I just feel like I'm getting the run around.

EDIT (Emails Removed):

Turns out the emails sent around clearly stated they were not allowed to be posted anywhere for public view. I was nicely asked to remove these emails from my blog.

This is where it's at now. I'm sure they will not get back to me until I bug them again. They are more than happy to take your order, but don't count on that one year warranty being honored. As far as the TS cells themselves, I'm so far quite pleased. I only ordered them from somebody in the US hoping to get the customer service support if needed.

I'm probably screwed on ever getting this thing fixed and might just design my own or mix and match a few other options out there.

So where should you buy these cells from now? Dave over at EVComponents is offering the cells and a different charger and BMS system. I kick myself, because his cell prices are about 70% of what I paid from EPS. Check out his website at http://www.evcomponents.com/. They are working at keeping these cells in stock! This means no more 2-3 month turn arouund times either. Very promising for the EV world.

Update: Elite is sending yet another module out to replace the defective one. Sadly, I've discovered another issue with another module. This module has a problem with one cell where it will randomly cut the voltage in half (display only, the cell is fine). This in turn is telling the charger, if charging, there is a low voltage condition. To the charger this means terminiate immediately and do not restart. I've been lucky on the timing and so far have not been stranded while I was debugging the issue. I've since reduced my low voltage trigger to just above zero to prevent yet more false alarms. I'll keep you posted on the results of the second module replacement as well.

Tuesday, May 26, 2009

DMV trip four

As you recall from trips two and three, I was told to come back when the registration was due. This would allow them to open the smog section in their computers so they could input the DMV ID number on the BAR cert and finally change the MP field from G to E.

Well, as I'm sure you can guess, the smog section still couldn't come up. They tried this and that, talking amongst themselves and about 30 minutes later...nothing. So the lady says, "Well your registration is due, would you like to pay and maybe that will open up the smog section?" What do I have to loose, I'm thinking. I pay and the computer spits out the new registration paperwork. Sure enough, the MP section is already set to E!

So, in hind sight I'm thinking their system has changed a bit. The BAR referee computer must now directly change type to avoid the whole DMV confusion process. I think if I would have waited for the due notice to come in the mail, I could have paid it online and received the updated E registration without any of the headaches I went through.

I have had a few people telling me that E means something else, or doesn't exist, etc. So I'm really not 100% sure if this is done, and won't know for two years when the smog would be due again. I think I'm good, but you never know with DMV. :)

Thursday, May 21, 2009

2500 and counting

OK, so there is one item I'm not completely happy with. The BMS from TS has some really great features all wrapped into one system. Many piece together things like amp meter, fuel gauge, etc. It was nice to find it all in one package, but this thing has been far from reliable.

You may recall my initial problems with charging where the BMS would freak out and start reporting cells at low voltages and such if the charger was at high amps.

The next thing I noticed was two cells that seemed to be sagging pretty bad under load. I placed a volt meter on them and they weren't sagging at all like the BMS reported. There are 5 modules, up to 10 cells connect to each. I switched around two of the modules and then I started getting two different cells (same module) that were reporting sag. I'm still waiting on a replacement from Elite Power Solutions. The first "replacement" didn't work at all and I had to send that one back.

I've also had a couple of occurrences where the charger just stops during the charge and I couldn't figure out why. I was at first assuming it was getting a little hot, so I started opening the trunk (until I get time to vent the trunk better). This seemed to fix it for a bit, but it started happening again. While driving the other day, the BMS alarm went off indicating one cell was about one volt lower than it really was (it immediately jumps back up to normal voltage). This has happened a couple of times now. During charging, any low voltage indication will terminate charging, so again the BMS shows its quality.

I have some plans to implement my own high and low voltage protection, and still use this BMS for the rest of it's functionality. This way if it blimps, it doesn't matter except for viewing purposes.

Thursday, May 14, 2009

1.21 Gigawatts!

I kept climbing up on the roof when I'd get home from work to see what they had accomplished.

Day1:

Here is a picture of some of the anchor bolts installed for one of the two groups of panels.

Here is a close-up of one. You see all the black caulking that goes into the drilled hole. Additionally the black piece of flashing will be over the bolt and hole with the higher shingle laid over this as well see later. This flashing allows most, if not all, of the water never even get near the hole.

Day2:

Here is the south facing group of rails installed. You can now see how each anchor is covered by the flashing and slide under the higher shingle.