I've been using the CellLog8 units for monitoring my high and low voltage for awhile now. I've yet to use the logging feature of the CellLog8S. Sadly I saved some money and only bought one unit that does the logging. I had to run seven seperate tests and the graphs don't match up for a really good comparison but I think the results still show what I wanted to know, "Which cells have had a significant increase in internal resistance".

The tests main goal was to take the cells to 3C (480 amps) and check for cells that are sagging too much.

All cells are connected with busbars except (15-16, 30-31, 37-38, 42-43, 45-46) which are connected with 2/0 cable.

This is the legend for cells 1-8 of each graph.

Cells 1 - 8

Cell 5 appears the be the worst of them. It sagged below 2.0v at 3C

Cells 9 - 16

These cells were fairly spread out from about 2.6v-2.85v. The lowest was 16 so this might be from any voltage sag across the cable.

Cells 17-24

This group was mostly 2.8v-2.9v except cell 19 around 2.6v.

Cells 25-32

This group had cells in the range of 2.4v - 3.0v. The two that stand out are cells 30(2.4v) and 32(2.6v). 30-31 seperate the from and rear packs and would be the area to show the most voltage sag so I don't think this cell is as bad as it looks.

Cells 33-40

This group had a wide voltage range as well. Cell 33 was the worst at about 2.5v.

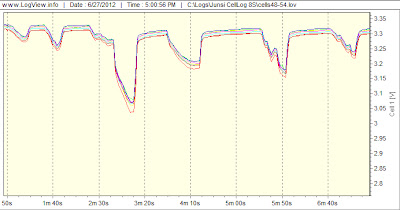

Cells 41-47

Nothing too bad here, worst cell being 47 at 2.8v.

Cells 48-54

By far the best group (these are all newer cells). All cells were around 3.05v-3.1v.

I'm frequently getting low voltage alerts (<2.5v) while driving and was curious how many cells were meeting this criteria. First I'll recheck the torque on the batteries, but assuming thtat is fine, it looks like I can replace the one cell and fix this. My normal driving never reaches 3C range unless I'm really needing to pass somebody. Replacing this one cell should remove the low voltage alerts most of the time. I have an extra cell sitting around that I've tested at 160Ah capacity. I'll replace cell 5 with it and hope the voltage sag on it is closer to the averages seen here.